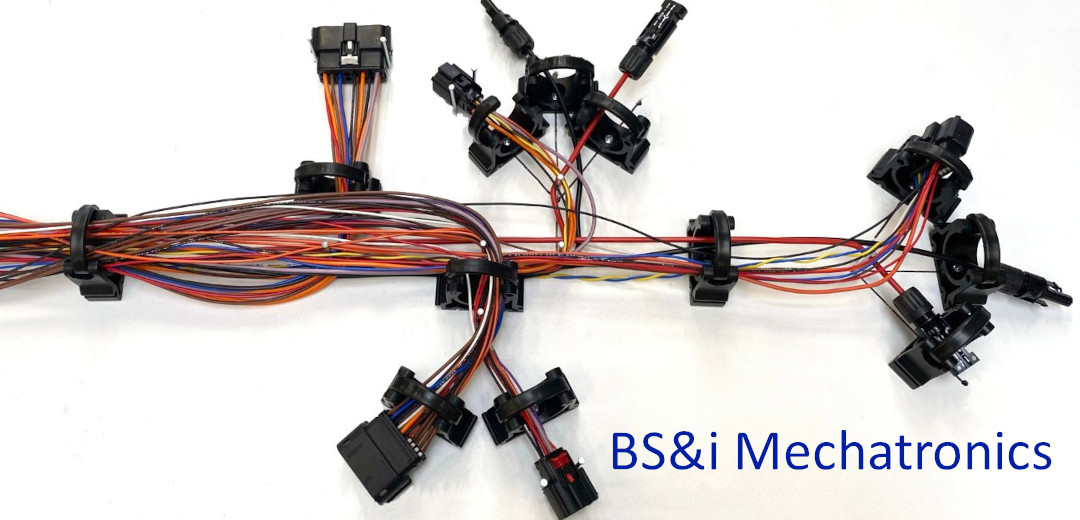

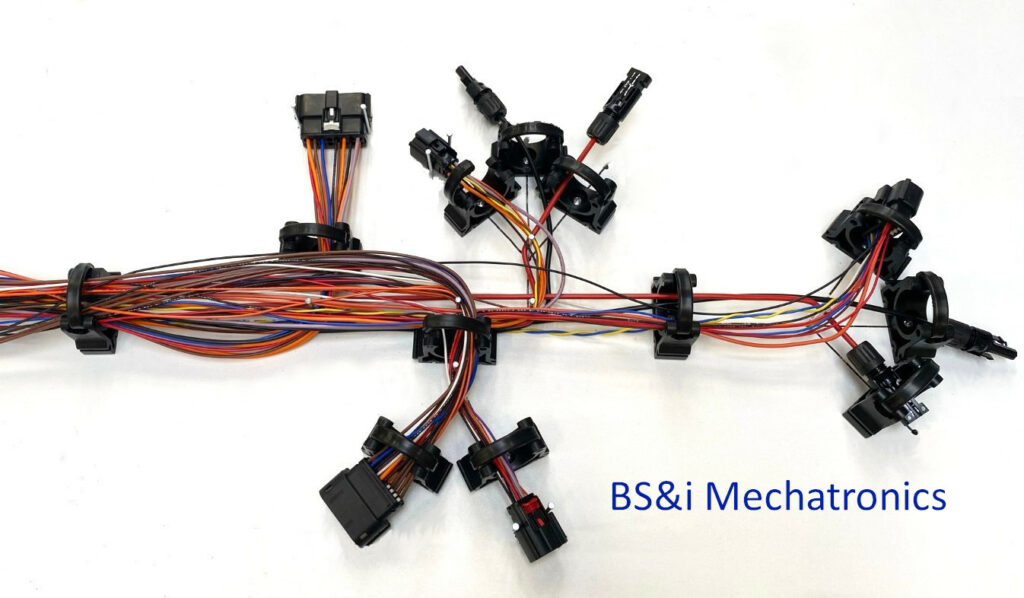

Assembling cable harnesses

Our new activity in addition to building and testing modules and devices. BS&i Mechatronics now also assembles cable harnesses for various applications. It concerns complex assemblies with data, signal, power and power supply up to and including simple cable harnesses.

Cause

The assembly of cable harnesses arose from the demand of our customers. Because we already build modules and devices for them, it turned out to be a small step for us to also supply cable harnesses. The argument for this is that our customers have a single point of contact at BS&i Mechatronics when it comes to supplying complete devices or parts thereof. The ultimate form of complete unburdening that saves time and costs for our customers.

Configurations

We now assemble various configurations, varying from a single cable with a connector to complex cable harnesses with a length of, for example, 5 m, 200 wires and 20 connectors for various applications. This entirely according to the specification of our customer. The series sizes vary from single pieces to 50 pieces. In principle, everything is possible.

Engineering and technology

We have been familiar with the techniques for assembling cable harnesses for some time. The technology for this is anchored in our more than 30 years of experience. We have this in-house and apply it daily, based on our electrotechnical and electronic know-how. Think of cutting and stripping wires, crimping contacts and mounting connectors. All this comes together on a so-called wire board. The cable harnesses are checked, tested and delivered packaged.

BS&i Mechatronics assembles and tests mechatronic devices and modules. We do this for a wide variety of customers, devices and markets.

If you have any questions regarding this article, please do not hesitate to contact us. Or visit our website at www.bseni.nl.